Basic Knowledge of Drills (4) Relief Surface

Dec. 15. 2021

In this article, we will discuss the “relief surface,” which is a component of the cutting edge of a drill.

About the relief

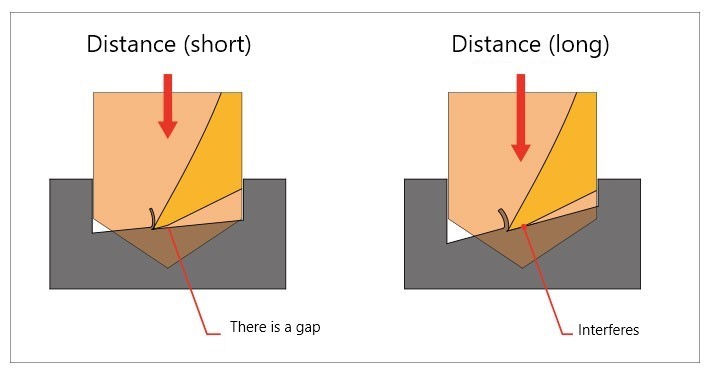

The “relief” or “relief surface” of a drill is a surface that slopes from the cutting edge to the back of the drill when viewed from the front.

The drill cuts the work material by moving forward in the axial direction while rotating, and the chips are ejected backward to make a hole.

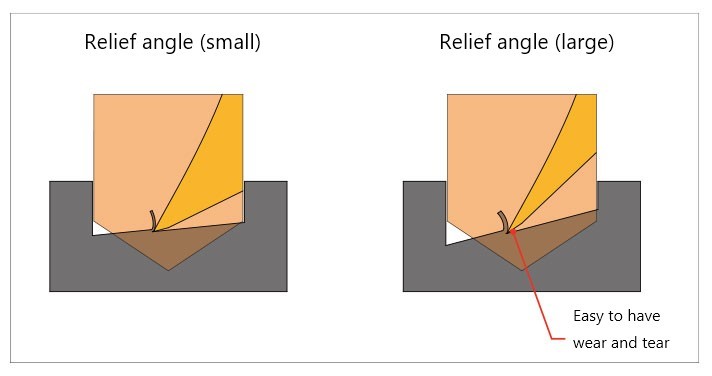

During the drill’s 180° rotation (in the case of a two-flute drill), if the feed is greater than the amount of slope on the relief surface, the surface behind the blade will interfere with the drill, making it impossible to cut into the material, and friction will cause wear.

However, if the angle is too large, the strength of the cutting edge will be insufficient and it will be prone to loss.

Definition of the relief

Relief Shape

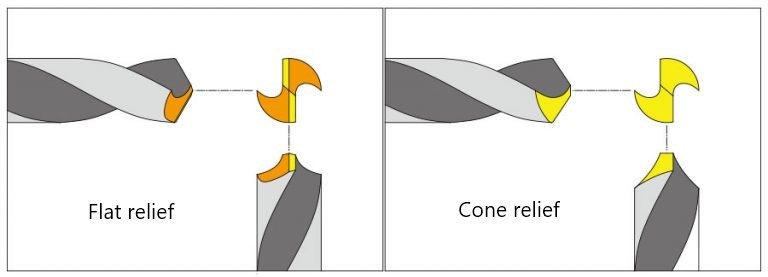

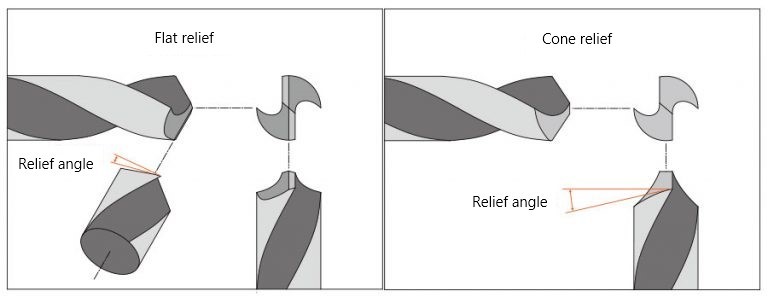

The shape of the relief can be roughly classified into two types: “flat relief” and “conical relief”.

Flat relief

The “flat relief” consists of a “first relief” and a “second relief” on the cutting-edge side. Depending on the shape setting, the back side of the second relief surface may be “higher”, in which case third relief may be added.

The advantage is that it is easier to secure the relief angle near the center. The disadvantage is that the strength of the cutting edge is slightly weaker than with a cone relief.

Cone relief

The cone relief consists of a single curved surface from the cutting edge to the back. Although the term “cone” is being used, it is not a cone in the strict sense, but a curved surface that ensures an inclination by shifting the position of the apex of the cone.

The advantages are that the cutting-edge strength is slightly higher than that of the “flat relief” and that it is easier to obtain a stable cutting shape when the shape of the work material is important, such as in chamfering or center drilling. The disadvantage is that it is difficult to secure the relief angle near the center.

Relief angle

In general, the definition of the relief angle differs slightly between “flat relief” and “cone relief”.

Flat relief angle

The definition of the angle of relief in “flat relief” is the angle that is inclined backward from the plane where the blade is parallel and the tip angle is inclined.

Since the relief angle is defined above, relief angle, and thinning, the rear side of the 2rd relief may be higher than the front side in the actual vertical condition depending on the setting of the tip angle, in which case the interference is prevented by the “3rd relief” to prevent the rear from being higher.

Cone relief angle

In the case of cone relief, the definition of the clearance angle is very vague and there is no right answer, but in general, it is the amount (angle) of the drop toward the rear in the axial direction at the periphery.

When grinding with a universal tool grinding machine or a grinder, the cone relief angle is sometimes defined as the angle at which the cutting edge is first applied (the angle at which the drill is tilted against the grinding wheel).

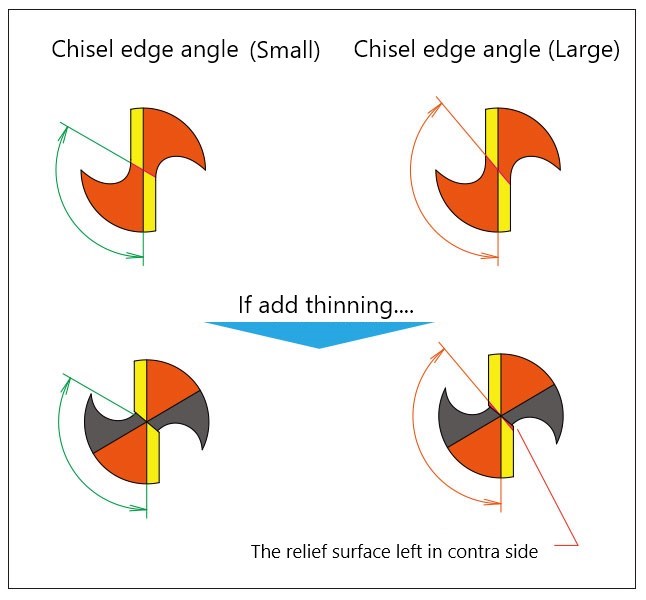

About Chisel Edge

The “chisel edge” is the ridge formed in the center (where there is no groove) by the relief surfaces of both cutting edges.

No cutting edge is created in this area, and it simply “pries” the work material when drilling.

The angle between the parallel of the blade and this “chisel edge” is called the “chisel edge angle,” and the angle varies depending on the tip angle and the relief angle.

The reason why we are explaining the chisel edge angle is that it has a great deal to do with the setting of the thinning, and depending on the setting, the cutting edge may not be configured in the thinning area, and the desired result may not be obtained.

General settings

Please refer to the table below for general settings.

| Type | Setting Value |

|---|---|

| HSS Drill(flat) | First relief angle 3° Second relief angle 20°~25° |

| HSS Drill (cone) | First relief angle 8° |

| Straight-edged carbide drills (flat) | First relief angle 10° Second relief angle 20° |

| Straight-edged carbide drills (conical) | First relief angle 8°~10° |

| Wave Flute Carbide Drills (Flat) | First relief angle 10° Second relief angle 25° |

| Wave Flute Carbide Drills (Cone) | First relief angle 8°~10° |

This is the end of the explanation of the drill relief surface.

<Previous> Basic Knowledge of Drills (3) Tip Angle