Regrinding drills on GriStar Series No.4 (Step)

Sep. 25.2021

This time we will discuss about step grinding. Step grinding can be done with the GriStar Multi 5 Axis and the GriStar SP.

About step drills

As the name suggests, it is a drill that has two or more diameters and is stepped. These drills are used for one-shot drilling of multi-stage holes, chamfering and zagging at the same time as drilling, reducing burrs in through holes, and improving hole accuracy.

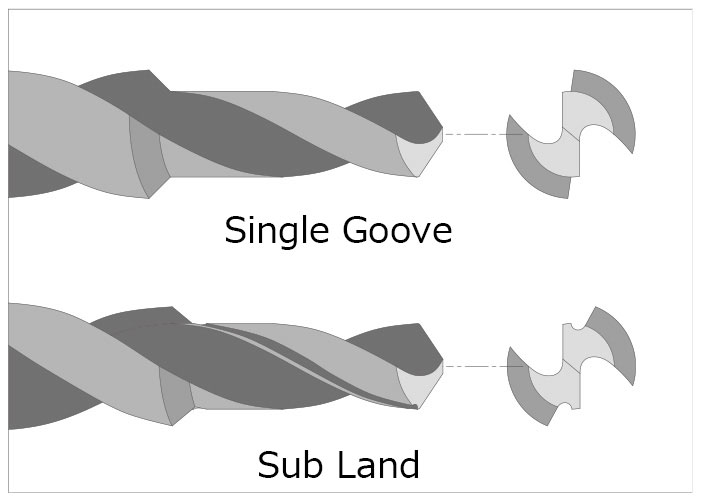

There are also two types of drills: single-groove stepped drills that use a common groove with the tip, and sub-groove stepped (sub-land) drills that have a groove for the stepped section. Sub-land drills are more costly because the grooving is done twice, but they have the advantage that the stepped neck section is stronger and less likely to break.

Relief shape of step drill

Like the tip, there are flat, cones, and flat cone shapes.

Flat

Flat relief consists of a first relief and a second relief. With the back of the second relief surface sometimes being higher, so a second relief plus conical rotary grinding may be used to prevent the back from being higher.

It is often used for counter burring and through-burrs reduction.

Cone

It consists of a second curved surface (cone). It is often used for chamfering.

Flat Cone

It consists of second flat relief + third cone relief (often without relief). And it is often used for chamfering with burnishing drills.

Try Setting

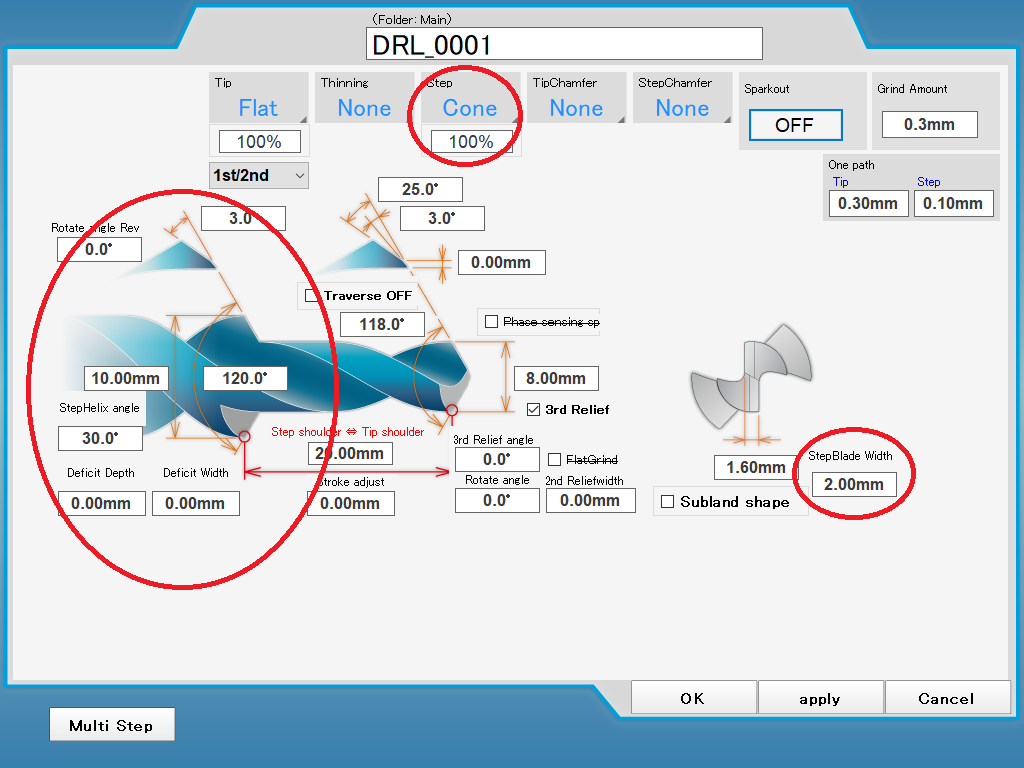

Click on the step shape tag at the top of the editing window and select the relief surface shape.

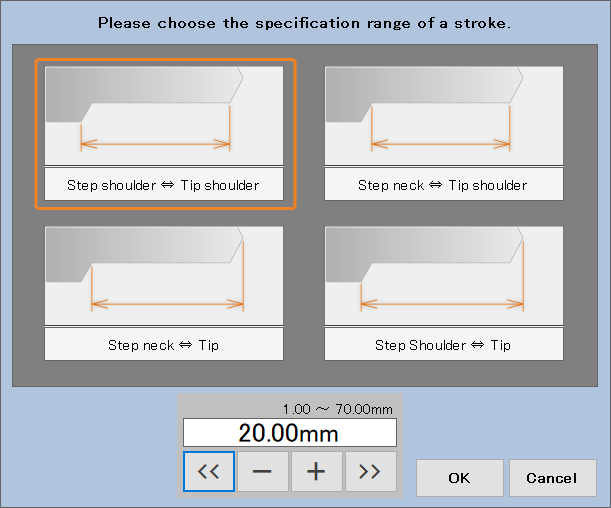

Enter the step angle, step blade thickness, relief angle, and stroke (length from the tip to the stepped portion). The stroke can be selected to define from any position of the tip to any position of the step.

Detailed settings and fine tuning will be explained later.

About the phase detection of the step part

You can select whether to sense the cutting-edge position of the stepped part or not on the tool set screen when sensing.

When Performing Sensing

When sensing … Note that if the input value of the blade thickness is different from the actual one, the step angle, second phase and third phase, and relief angle of the ground shape will be different from the settings. If the step shape (especially the step angle) is the same as the current one or close to it, this method is better.

When Not Performing Sensing

The step position is calculated from the tip of the blade. It is necessary to input the helix angle strictly. This method is recommended when the desire step angle is different from the actual one, or when this grinding is after rough step processing.

That’s all the “Regrinding drills with the GriStar Series Automatic Tool Grinding Machine” column. We would like to explain the details of each parameter later on.

In the next article, we will introduce “Re-Grinding endmills with the GriStar Series Automatic Tool Grinding Machine”. Thank you for your continued support.

<Previous> Regrinding drills on GriStar Series No.3 (Thinning)

<Next> Regrinding endmills on GriStar Series No.5 (2F Endmill)