Regrinding endmills on GriStar Series No.2 (3F~6F Endmill)

Oct. 08.2021

In this article, we will look at the range from 3 to 6 flute end mills, as they all have a lot in common.

About Bottom Blade Shape

The bottom edge of 3 to 6 flute end mills varies in type depending on the tool material and usage, but it is basically a combination of the position and depth of the relief surface and gash. It features a gash with an acute angle grinding wheel rather than a large gash like a two-flute end mill.

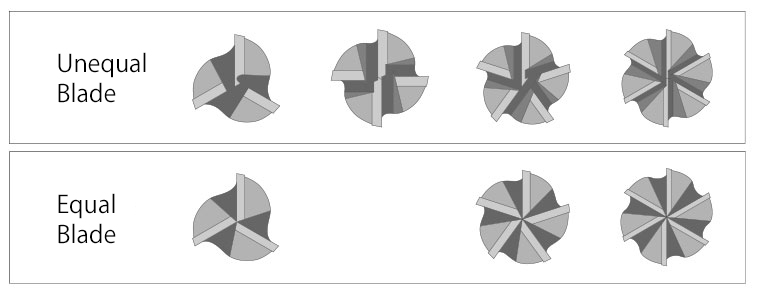

Unequal Blade

It consists of a longer blade that extends to or beyond the center and other shorter blades. Since the cutting edge extends to the center and chip evacuation around the center is possible, it is selected when machining in the Z direction or when the cutting width is large.

Equal Blade

All cutting edges are of equal length, and the cutting edge is up to the center. Suitable for precision machining and light cutting, but not good at machining in the Z direction. (In the GriStar series, the 4-flute endmill software has only Unequal Blade Settings).

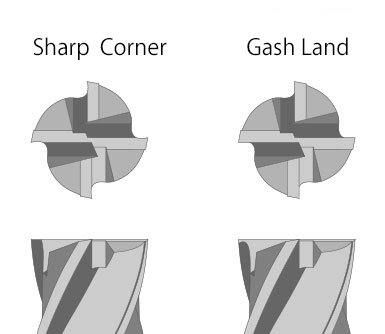

Sharp Corner

The rake groove is utilized near the outer periphery to form a sharp cutting edge. It is often used in HSS end mills with high toughness.

Gash Land

The gash is applied to the cutting edge by the rake groove on the outer edge to make the cutting edge obtuse. This is often used for carbide end mills that do not have toughness.

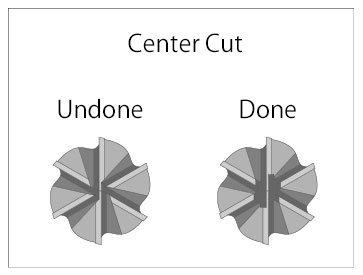

Center Cut

In the case of a 6-flute endmill with unequal blades, a cut is made near the center to improve chip evacuation near the center.

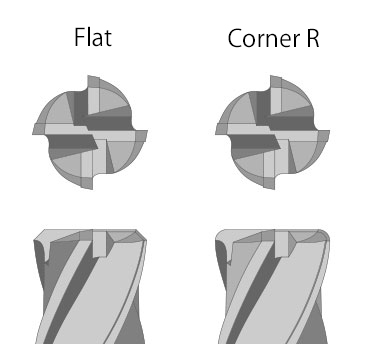

Corner R

A Chamfer face or Relief face flank is attached to the outside of the cutting edge. Used to prevent chipping and for Chamfer face machining. (5 flutes and 6 flutes tools are only available with flat chamfer)

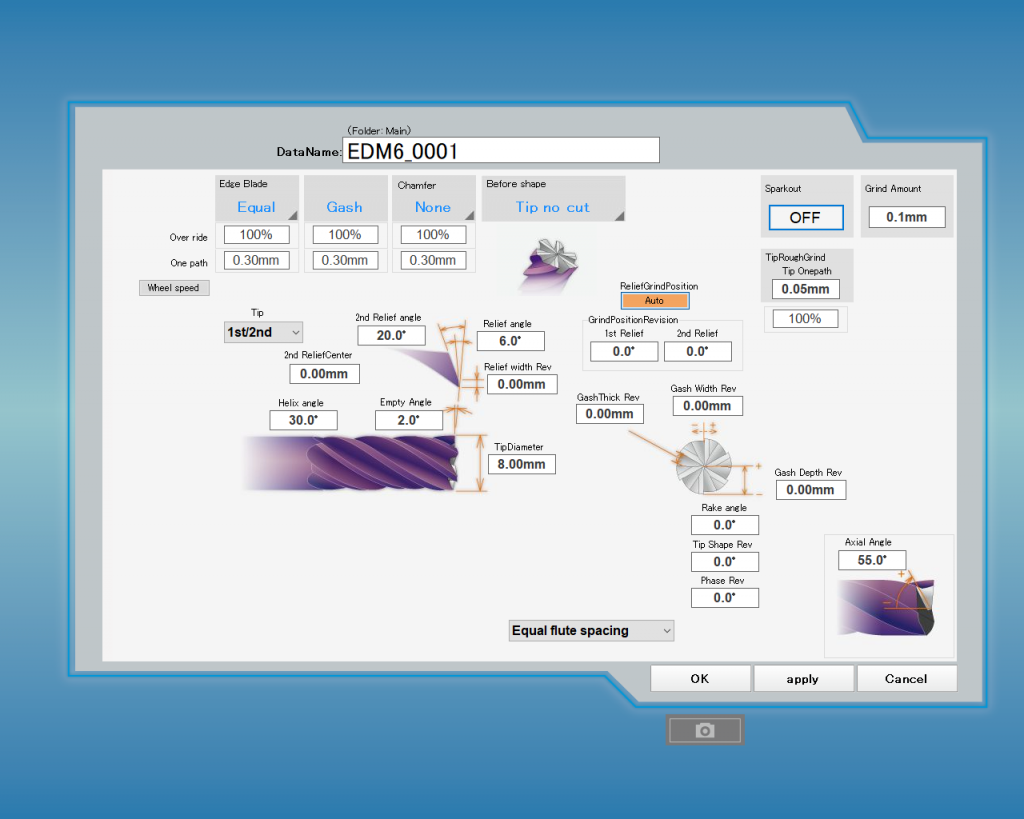

Try Setting

Click on the “Bottom Edge” tab at the top of the editing window to select the bottom edge shape. When you have finished selecting, set the relief angle and gash parameters.

The following is a list of typical shapes and their parameters (reference values).

| Parameter | Parameter Value |

|---|---|

| Concave Angle | HSS:2° Carbide:0° |

| Rake Angle | HSS:2° Carbide:0° |

| Gash Land Angle | Sharp Corner:0° Gash Land:About 1~5° |

| Gash Width Revision | Unequal blade: Set slightly minus direction so that the center will not be cut Equal blade: Adjust so that the gash gathers in the center. |

| Others | Use the default values as a base and adjust as necessary. |

There are many other parameters that can also be adjusted, we will explain the details next time.

<Previous> Regrinding endmills on GriStar Series No.1 (2F Endmill)

<Next> Regrinding endmills on GriStar Series No.3 (Ball End Mill)