Regrinding Taps on GriStar Series

Oct. 17. 2021

In this article, we will discuss about tap’s regrinding on GriStar Series regrinding machines.

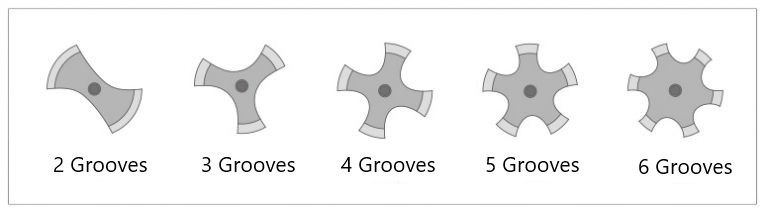

Applicable Shape

The GriStar series regrinding machines are applicable for regrinding cutting taps which are used for metric threads and unified threads. The GriStar SP (GSP) and GriStar Multi Evolution (GME) are applicable for 2 to 4 grooves taps regrinding, while the GriStar Multi 5 Axis (GM5) is applicable for 2 to 6 grooves taps. For other applicable tool diameters and shapes, please refer to the comparison table below.

| Parameter | GSP | GME | GM5 |

|---|---|---|---|

| Effective diameter (Meter) (Unify) (Direct Enter) | M3~M20 No.5~5/8 - | M3~M16 No.5~5/8 3.00mm~30.00mm | M3~M27 No.5~3/4 3.00mm~27.00mm |

| Grooves | 2~4 | 2~4 | 2~6 |

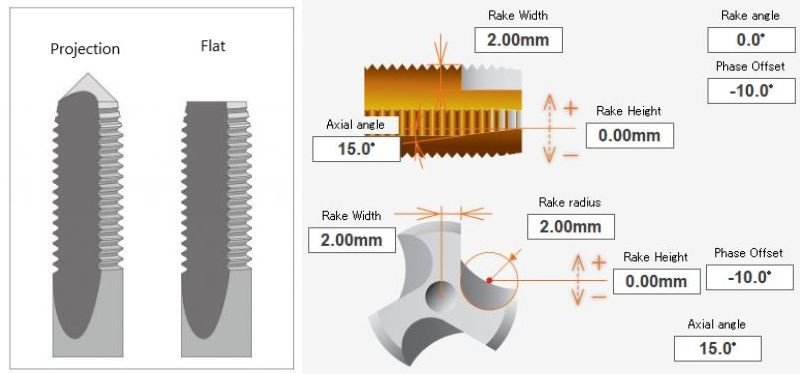

| Tip Shape | Flat Projection (Effective diameter up to 8mm) | Flat Projection (Effective diameter up to 8mm) | Flat Projection (Effective diameter up to 8mm) |

| Pitch | 0.35~2.5 | 0.35~3.5 | 0.35~3.5 |

| Rake surface Regrinding | Flat | Flat | Flat R |

| Helix Direction | Right Hand | Right Hand Left Hand | Right Hand |

| Helix angle | -20°~+45° | -45°~+45° | -20~+45° |

Try Setting

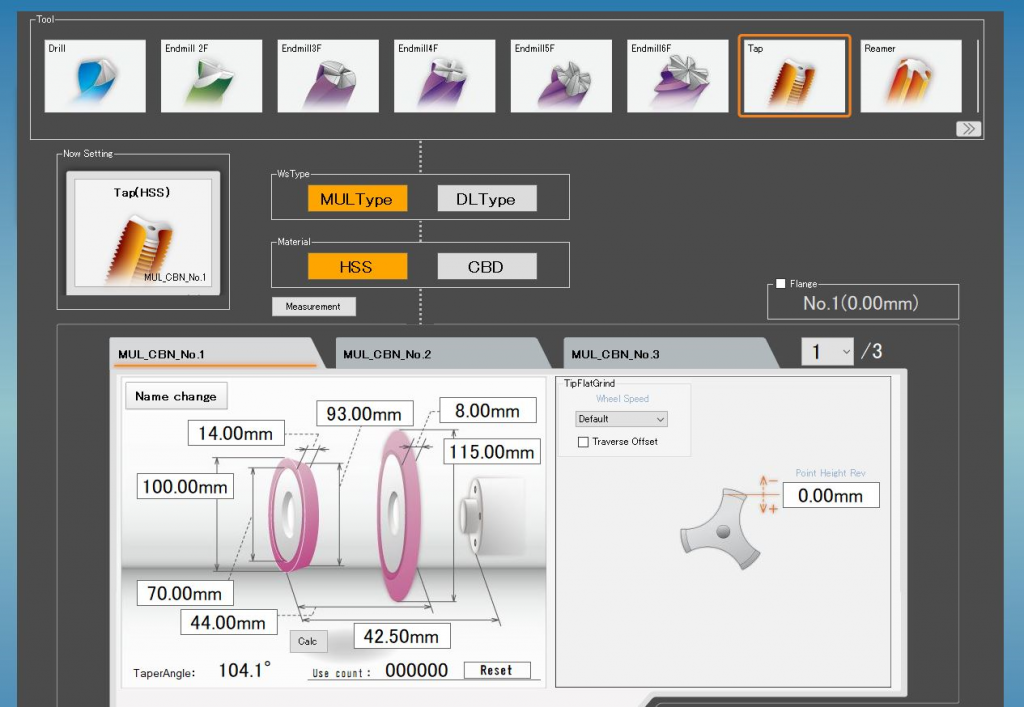

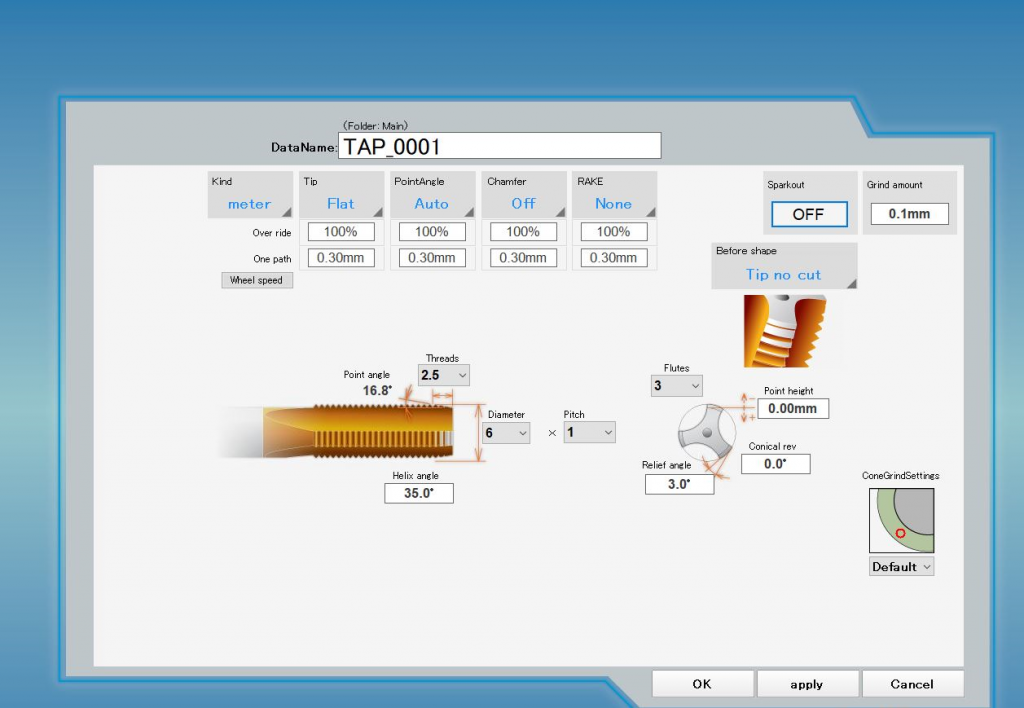

Click the “Tool Type Setting” tag in the upper left corner to switch the tool type to “Tap”, and change the grinding wheel accordingly.

After entering the dimensions of the grinding wheel and replacing it, set up the tool parameters.

The main setting items are as follows.

Kind… Select the standard from meter, unify, or direct input (GME, GM5).

Tip … Select the tip shape from “Flat” and “Projection”. “The projection tip can only be selected for effective diameters of 8 mm or less.

Point angle … The angle of the leading part. Normally, it is calculated automatically from the pitch and the number of threads, but you can also enter it directly. In that case, click the point angle tab and switch from “Auto” to “direct”.

Chamfer … If the tip is flat, chamfering can be performed.

Rake …. The rake groove of the leading part can be ground. Select from “None”, “Flat” or “R” (GME only).

Tip cut/ Tip no cut … Set to “Tip cut” if the leading area is cut before performing grinding. This selection is made for preventing a large load to the grinding wheel.

Flutes … Enter the number of flutes (number of grooves).

Tip diameter … Effective diameter of the tool. Select a standard from meter, unify, or direct input the data.

Pitch … Enter the thread pitch of the tool.

Threads … Enter the grinding length by the number of peaks.

Helix angle … Enter the helix angle of the tool.

Relief angle … Set the relief angle of the leading part.

Rotation compensation … If the tap groove is too shallow and the leading part is too wide, unground part may appear at the rear of the relief. In this case, enter a positive value. In the case of the blades interfering with the next blades, enter a negative value.

This is the end of the tap regrinding article. In the next article, we will discuss about reamer’s regrinding.

<Previous> Regrinding endmills on GriStar Series No.5 (Flute)