Regrinding drills on GriStar Series No.3 (Thinning)

Sep. 19.2021

In this article, we will discuss the settings and parameters of the thinning shape of cutting tools.

About thinning

We are sure you all know about thinning, but we would like to give you a brief explanation.

The cutting edge of a drill consists of a relief surface and a spiral groove (rake), but the center area without the groove (chisel edge) does not have a cutting edge. Therefore, even when drilling, the chisel edge only crushes and deforms the work material, which causes large thrust resistance, reduced centripetal force, and poor chip evacuation.

Therefore, thinning is a method of making a cut in the center to shorten the chisel edge and improve thrust resistance, centripetal force, and chip evacuation.

Types of thinning

There are various types of thinning available, and this article will introduce the thinning shapes that can be ground with the GriStar series.

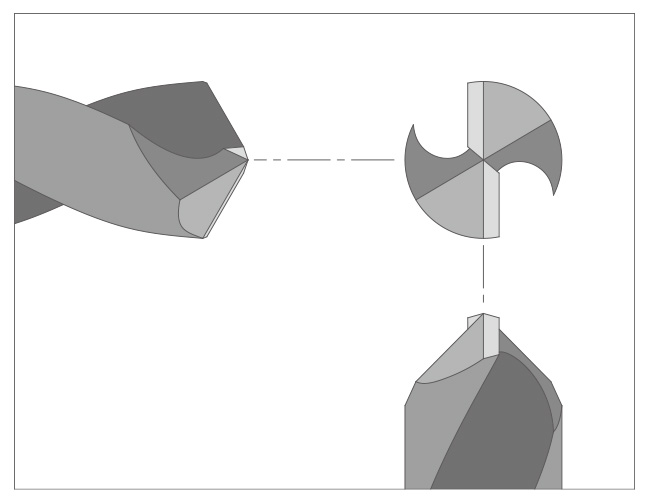

X Thinning

Short chisel edge, low thrust resistance, and excellent centripetal force.

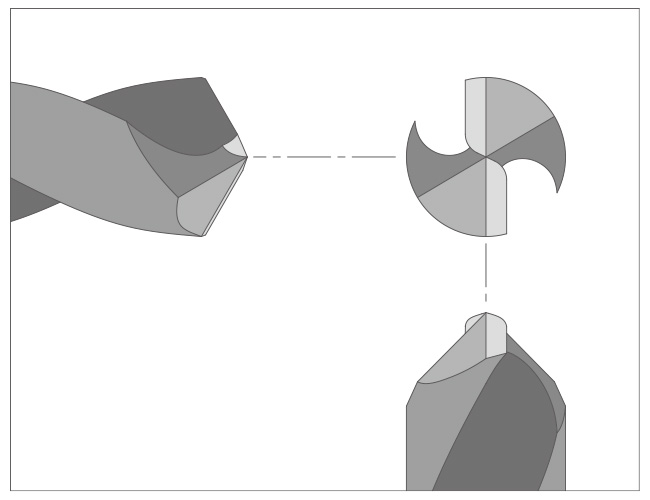

R Thinning

Suitable for heavy-duty drills with large core thickness. Good chip evacuation.

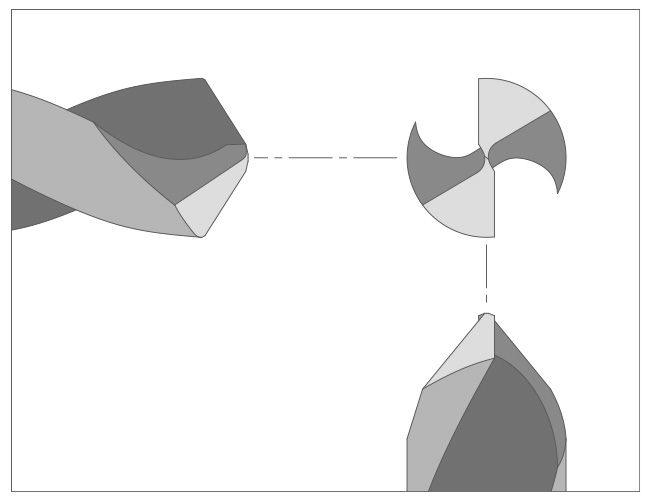

S Thinning

Good chip evacuation and high strength of chisel section. For drills with small tip angle (acute angle) and thin core thickness. (Example: Leading drill)

A Thinning

It is also called a three-rake, which owns good centripetal force, especially suitable for drills with thin core thickness.

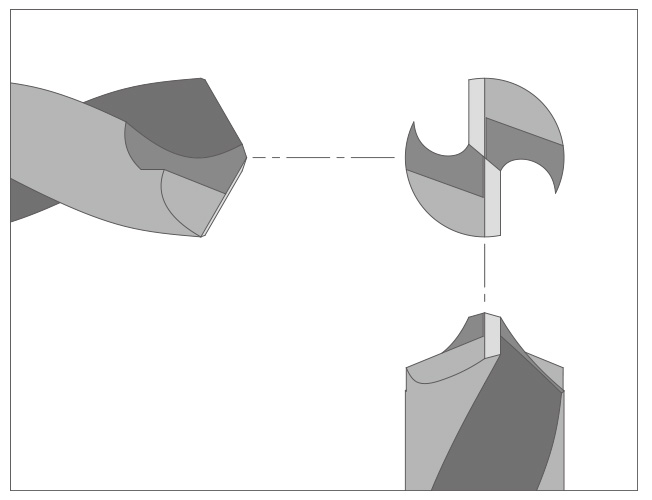

BN Thinning

Good chip evacuation and high strength of the chisel edge. Depending on the parameter setting, the rake angle of the cutting edge can be increased (back of the blade) to prevent chipping of the cutting edge. Especially suitable for burnishing drills.

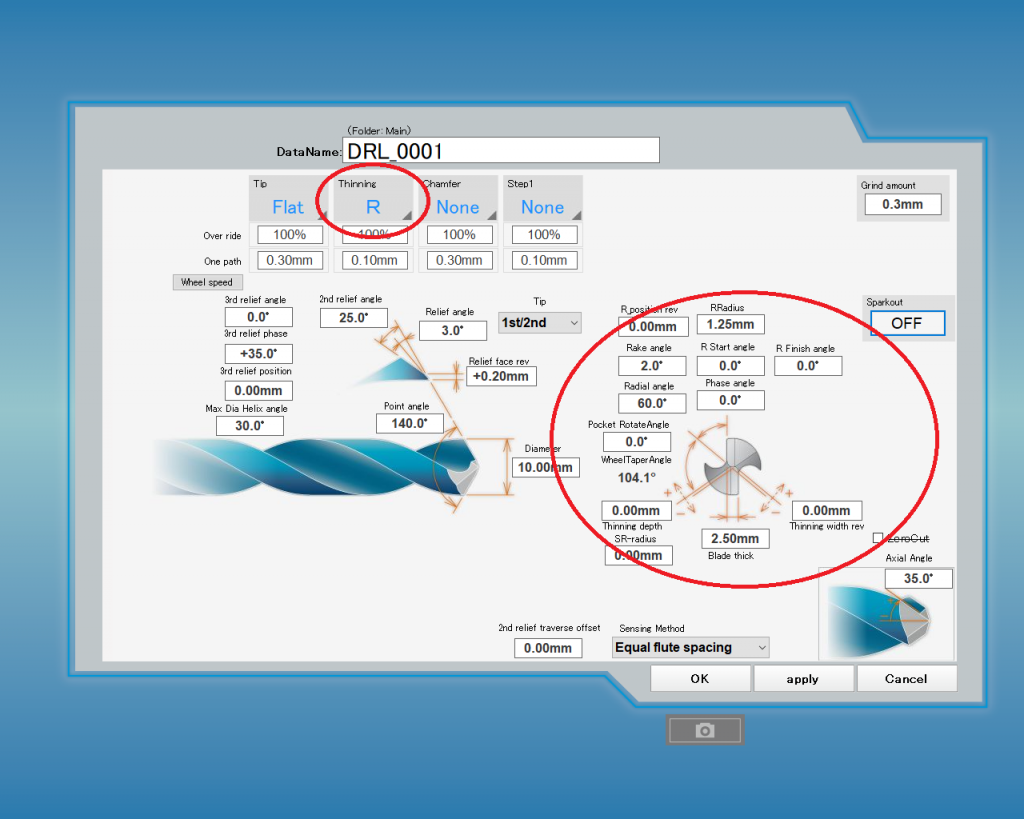

Try Actual Setting

Now let’s try to set up the thinning parameter.

First, click on the “Thinning” tag at the top of the edit screen and select a thinning shape from the list.

Next, set the thinning parameters. If there are no special instructions, just try grinding with the specified values first.

Each parameter value is different depending on the thinning shape. I would like to explain the parameter settings for each thinning shape next time.

The following are general parameter setting values (for reference).

| X | R | S | A | BN | |

|---|---|---|---|---|---|

| Radius Angle | 45° | 60° | 35° | No Setting | 5° |

| Pocket Return Angle | 0° | 0° | 0° | No Setting | 0° |

| Axial Angle | 35° | 35° | 35° | 40° | 35° |

| Rake Angle | HSS: 2° Carbide: 0° | HSS: 2° Carbide: 0° | HSS: 2° Carbide: 0° | No Setting | HSS: 2° Carbide: 0° |

| R Radius | No Setting | Blade thickness/2 | Blade thickness/2 | No Setting | No Setting |

That’s all there is to know about the thinning shape.

<Previous> Regrinding drills on GriStar Series No.2 (Relief)