Basic Knowledge of Taps (1) What is a Tap?

Mar. 2. 2022

From this time on, we will explain about the tapping process, which is indispensable in metal processing.

What is a tap?

According to JIS (Japanese Industrial Standards), a tap is “a male thread type tool that forms a female thread in the down hole by mainly rotating and feeding according to the lead of the thread.

In other words, a tap is a tool to perform female thread processing on a work material, and tapping is an indispensable process to connect bolts with other parts in the case of producing machine parts.

Types of Taps

First, taps can be roughly classified into two types: cutting taps, which make female threads by cutting, and raised taps, which make female threads by plastic deformation of the work material.

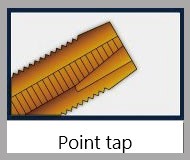

Cutting Taps

Cutting taps are used to make female threads by cutting the prepared hole and ejecting chips. It can be used for tapping even with hard materials or materials that do not have good ductility, and is generally used in all situations because the machining conditions are not too strict.

The disadvantages are that chips tend to accumulate in stop holes, and that thread accuracy and strength are inferior to raised taps.

Cutting taps are classified into several types depending on the groove shape.

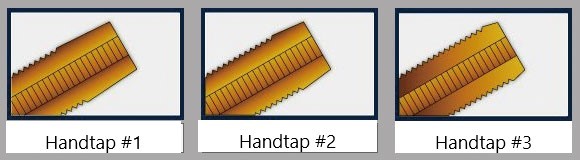

Hand tap

It is originally designed to perform tapping by hand, so it’s possible to change the bite length from 1st (initial), 2nd (intermediate), and 3rd (finishing), and work manually without applying load.

When tapping with a machine, the bite length is usually about the 3rd position.

Straight grooves (not spiral) are often used because they have strong cutting edges and can handle hard materials, and are easy to re-grinding.

Point taps

This is a tap with a straight groove, but with a reverse-twist groove on the biting part of the tip.

Since the twisting groove is in the opposite direction of the tap’s rotation direction, chips are ejected in the downward direction. In through holes, chips are easily ejected and high-speed processing is possible.

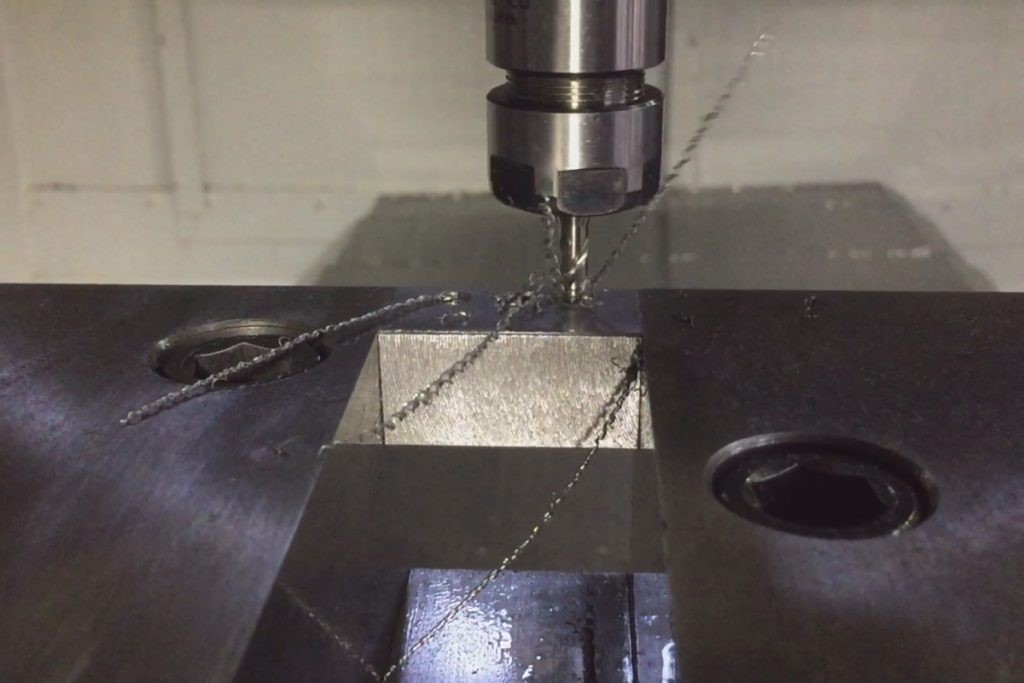

Spiral tap

The spiral tap has the same twisting groove as the drill. Chips are ejected in the upward direction.

In the case of a stop hole, tapping can be done all the way to the bottom of the hole and chips will not accumulate. Since the rake angle is set, the cutting performance is also excellent.

Thread forming tap

This is called a “rolled tap” or “thread tap” depending on the manufacturer. A female thread is created by plastically deforming the lower hole.

Since the preparation hole is deformed, no chips are produced, and the risk of scratches to the work material due to chips wrapping around is reduced. In addition, the accuracy of the thread is stabilized and the strength of the thread is increased by plastic deformation.

However, since the female thread is rolled, it is not suitable for work materials that are not ductile. In addition, if the preparation hole is not properly controlled (on the order of 0.01mm), the threaded hole may become loose or the top of the screw head may crack. Since the entrance of the female thread tends to swell due to deformation, it is necessary to control the accuracy of the entrance area.

<Previous> Basic knowledge of end mills (2) Elements that make up an end mill

<Next> Basic Knowledge of Taps (2) The Elements that Make Up a Tap