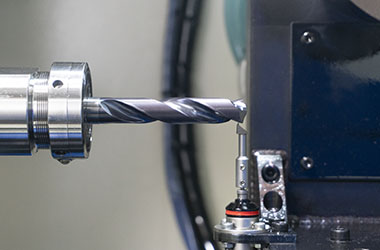

For Improving Tool Grinding, Polishing Efficiency

Nikko Denki Co., Ltd., a parent company of us, has accumulated a great deal of experience and processing know-how in the mass production of metal workpieces.

In order to pursue high quality in metalworking, outstanding knowledge and skills in tooling are required. Thus, we have been researching how to utilize these skills “easy to be utilized by anyone“, “with the same quality” and “as efficiently as possible“.

Since then, we have developed the GriStar Series of automatic tool grinders, which have been receiving great instructions by manufacturers that using a great number of machines, as well as professional grinders who specialized in tool grinding and polishing.

Concept For Developing GriStar Series

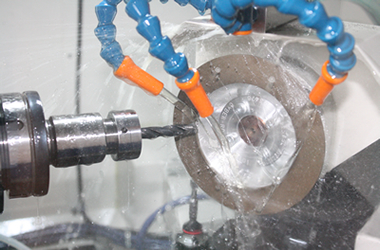

At the professional metal processing working site, it is essential to keep tools in optimum condition at all time to ensure high quality and work efficiency. For this reason, the regular maintenance is very important. But the greater the types and quantities of tools are, the greater the time and the craftsmanship of the specialist personnel are required.

Therefore, the GriStar Series were developed based on this three product concepts: 1) easy to operate for anyone, 2) high-precision grinding and polishing, 3) as fast as possible.

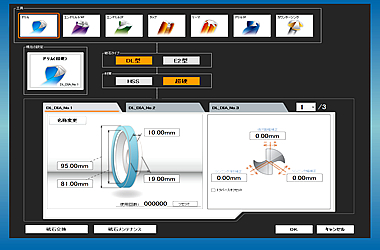

For Achieving Easy Operation

- Intuitive operation by easily viewable graphic

- Instant starting without programming

- Easy tool installation by spring collet

For Achieving High-precision

- The edge blade can be set as desired by data entry

- Possible to retrieve the stored data at anytime

- Measure by high-precision block stylus

For Achieving Speedy Work

- Reduce set-up time and arrangement time dramatically

- Increase grinding speed by compact, efficient movement

- Reduce unnecessary processes by utilizing the characteristics of 5 or 4 axes