The GriStar Multi Evolution can grind four types of cutting tools (drill, end mill, tap and reamer) in one machine.

As an automatic tool grinder, its outstanding operability and abundant data storage allow for the same precision of tool grinding regardless of who the operator is.

“Easy to operate for anyone” is the biggest feature of the GriStar Multi Evolution.

※Click to enlarge

4 types of cutting tools can be ground

The GriStar Multi Evolution is capable of grinding four types of cutting tools: drill, end mill, tap and reamer.

The machine is compatible with both HSS and CBD, and can grind 4 types of tools and 2 types of materials. Namely, a total of 8 types of automatic tool grindings are possible.

| Tool Type | Material | Flutes | In-House Wheel Model Number |

|---|---|---|---|

| Drill | HSS | No. /2, 3 | GM_DL CBN RB |

| CBD | No. /2, 3 | GM_DL DIA RB | |

| Endmill | HSS | No. /2, 3, 4 | GM_E2~4 CBN RB |

| CBD | No. /2, 3, 4 | GM_E2~4 DIA RB | |

| Tap | HSS | No. /2, 3, 4 | GM_DL CBN RB |

| CBD | No. /2, 3, 4 | GM_DL DIA RB | |

| Reamer | HSS | No. /4, 6, 8 | GM_DL CBN RB |

| CBD | No. /4, 6, 8 | GM_DL DIA RB |

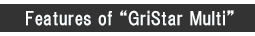

Outstanding operability

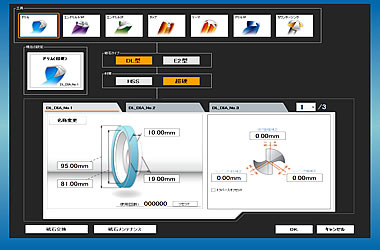

The GriStar Multi features easy operation with the easily viewable graphical display.

The machine employs collet chuck for clamping the tool, which makes tool grinding simple.

In addition, the machine has an offset compensation function that automatically measures the tool and compensate for the error to a minimum.

Operation screen sample (click to enlarge)

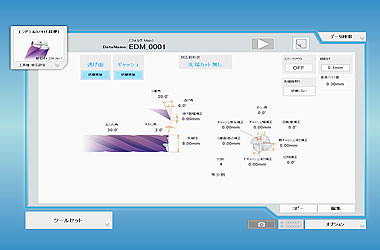

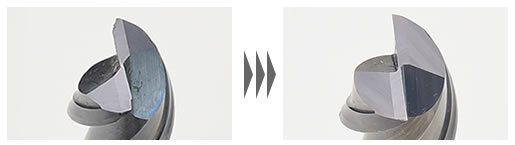

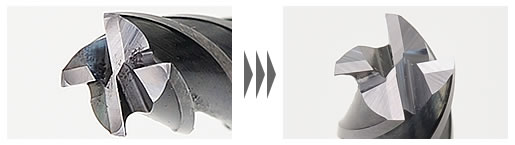

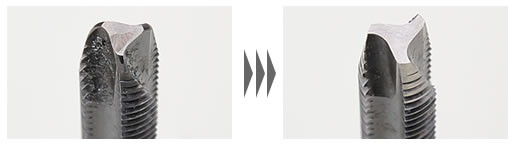

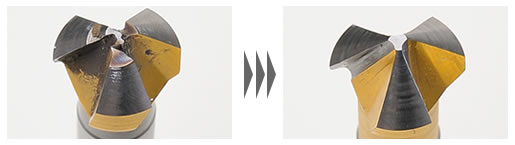

Faithful reproduction of the cutting edge

With GriStar Multi Evolution, you can set the tool data by yourself, such as the drill 1st relief, 2nd relief angle or the tip shape and so on.

Not only can they be made into the exact same shape as the new one, but they can also be made into an original shape suitable for the work.

Grinding sample

- Drill 2 Flutes

- Endmill 2 Flutes

- Endmill 4 Flutes

- Tap

- Countersink

Instant starting without programming

The GriStar Multi Evolution is capable of storing 5000 items of data for each tool. And the stored tool data can be easily retrieved.

It is also possible to manage the data by dividing it into folders according to its use, so the efficiency of data retrieving can be dramatically improved.

In addition, the tool installation is using the one chuck method, so it can be completed easily and in a short time without using other special tools.

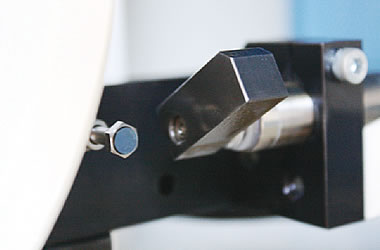

Use contact type block stylus for high-precision

The measurement accuracy supports the high-precision of grinding. The GriStar Multi Evolution uses the block stylus in touch probe for high accuracy and high-speed measurement.

Faster and more accurate measurement of the cutting edge is now possible.

Improve functionality by software upgrades

Upgrading software, such as improving cutting methods and adding new functions, can be accomplished simply by importing digital data from a USB instead of replacing the control board.

You will be able to take advantage of the latest features even after the equipment is installed.

| Machine specification | Description | GriStar Multi Evolution |

|---|---|---|

| Model number | GME-200V | |

| Dimensions (Frame included) | W670mmxD720mmxH1,500mm | |

| Net weight | Approx. 250kg | |

| Tool clamp | Spring collet Chucking way | |

| Tool measurement | Touch sensor | |

| Wheel spindle | 750w Servo control | |

| Wheel | DIA Resin/CBN Resin | |

| Control Axis | 4 Axes simultaneously control | |

| Coolant oil supply | Complete wet process by coolant pump | |

| Coolant oil | Oil based cutting fluid/under 25cSt (water insoluble) | |

| Monitor | LCD monitor (1280×1024 SXGA) | |

| Power source | ||

| Single ph. 200~240V 1.1Kw 50/60Hz (200V) | ||

| Operation | USB mouse | |

| External port. | USB2.0×4(one for mouse) | |

| Usage environment | Indoor only | |

| Recommended ambient temperature | 20℃~30℃ | |

| Ambient humidity | 45%~80% | |

| Applicable tool material | HSS/CBD | |

| Range of tool length | 45mm~200mm | |

| Applicable tool shape | Right flute/Right hand/Left hand (tap, reamer) | |

| Language display | Japanese/English/Korean/Chinese(traditional/simplified) switchable | |

| Grind setting specification | Drill |

Flute: No. /2, 3 Tool size: (1.0) 3.0~20.0mm Tip shape: flat, cone Thinning: X, R, A Chamfer: flat, cone |

| Endmill |

Flute: No. /2, 3, 4 Tool size: 4.0~20.0mm Tip shape: square (opt. unequal flute) Chamfer: flat, edge tip round corner |

|

| Tap |

Flute: No. /2, 3, 4 Tool size: M3~M20 Pitch: 0.35~2mm Threads: 0.5~9 Chamfer: cone |

|

| Reamer |

Flute: No. /4, 6, 8 Tool size: φ4~φ20 Tip shape: flat (opt. unequal flute) Point angle: 30~45° |

|

| Countersink |

Flute: No. 3 Tool size: φ1~φ20 Point angle: 55~125° |

|

| Others | Respond to special tools | |