Outstanding operability

The GriStar SP is a user-friendly machine by its easy-to-view screen operation and ease of tool installation.

Also, the fully automatic grinding system ensures stable accuracy.

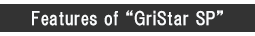

Operation screen sample (Click to enlarge)

Instant starting without programming

The GriStar SP is capable of storing data from over 10,000 items of tools. And the stored tool data can be easily retrieved with a screen touch.

It is also possible to manage the data by dividing it into folders according to its use, so the efficiency of data retrieving can be dramatically improved.

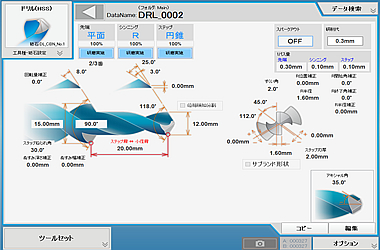

In addition, the tool installation is using the one chuck method, so it can be completed easily and in a short time without using other special tools.

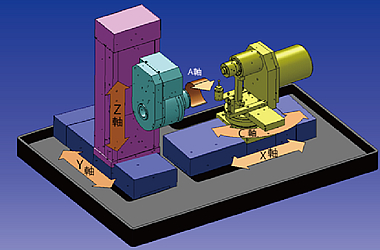

5-axis simultaneously control

5-axis grinding simultaneously control enable accurate positioning of works, and makes it possible to perform special types of grinding that were only possible with skilled workers.

The 5-axis control allows grinding to be completed with a minimum movement line, also reduces the grinding time.

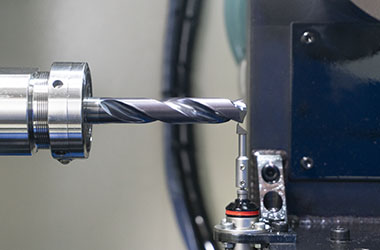

Use contact type block stylus for high-precision

The measurement accuracy supports the high-precision of grinding. The GriStar SP uses the block stylus in touch probe for high accuracy and high-speed measurement.

Faster and more accurate measurement of the cutting edge is now possible.

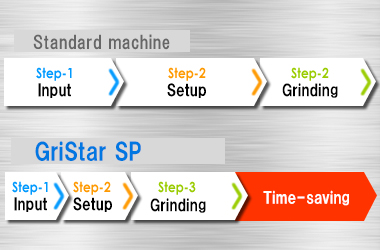

Higher work efficiency

The efficiency of the work time from mechanical design to completion of the work is of great benefit to the companies. With GriStar SP, you can easily retrieve the stored tool data and install a tool with one touch, which dramatically reduces the time from set-up to preparation.

When grinding a large variety of products or small lots, productive and a significant machining time difference can be made depending on work efficiency. It’s exactly a profitable tool grinding machine.

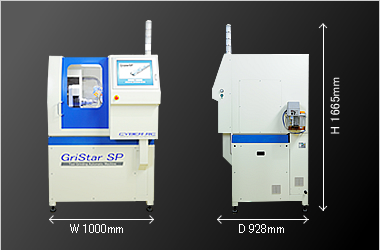

Even in narrow places

The GriStar SP has about 1/3 of the occupied area of a competitor’s grinder, remarkedly reducing the interference with other machines and problems with movement lines.

When replacing an existing machine, such as a grinder, the extra space allows for an efficient flow line.

| Overall | Description | GriStarSP |

|---|---|---|

| Model number | GSP | |

| Dimensions | W1000mmxD928mmxH1665mm | |

| Net weight | Approx. 460kg | |

| Coolant tank dimensions (Include mist collector) |

H860mmxW500mmxD850mm | |

| Coolant tank weight | Approx. 90kg | |

| Power source | 3Phase 200V 4.5kva (Japan) | |

| Work chucking | Spring collet | |

| Work position detection | Contact type touch probe | |

| Operation | Interactive 15-inch touch panel | |

| Operation indicator lamp | 4 lights (White: stand by, Green: in operation, Orange: warning, Red: emergency stop | |

| Light inside | LED(2,100lx) | |

| Lubricant supply | With automatic oiling pump | |

| coolant oil | (Water insoluble) oil based cutting fluid/ under 25cSt | |

| Lubricant | Sliding surface oil (ISO VG32 recommendation) | |

| Control Axis | Axis number | 5 (X,Y,Z,C,A) |

| Control motor |

A, C stepping motor with encoder X, Y, Z Servo motor |

|

| X-Axis drive system | Linear motion by ball screw | |

| Positioning control precision | 0.002mm | |

| Max. moving speed | 4.32m/min | |

| Max. moving distance | 180mm | |

| Y-Axis driving system | Linear motion by ball screw | |

| Positioning control precision | 0.002mm | |

| Max. moving speed | 4.32m/min | |

| Max. moving distance | 180mm | |

| Z-Axis driving system | Linear motion by ball screw | |

| Positioning control precision | 0.002mm | |

| Max. moving speed | 2.88m/min | |

| Max. moving distance | 180mm | |

| C-Axis driving system | Belt drive | |

| Positioning control precision | Approx.0.004°(1/255°) | |

| Max. rotation speed | 6rpm | |

| Max. rotation angle | +15°~ -90° | |

| A-Axis driving system | Belt drive | |

| Positioning control precision | 0.006° | |

| Max. rotation speed | 24rpm | |

| Max. rotation distance | ∞(CCW) | |

| Grinding wheel spindle | Motor | Magnet motor |

| Motor output | 2.2kw | |

| Drive system | Belt drive | |

| Control system | Inverter control 3 steps tranmission | |

| Spindle | Made by Cyber RC | |

| Wheel device | Boss flange | |

| Wheel material | CBN/DIA | |

| Wheel speed | 1200 / 1800 / 2000 (m/min) | |

| Stopping time | Max. 7sec | |

| Drill specification | Grindable shape | Right flute right hand; right flute torsion fee |

| Flute | 2 | |

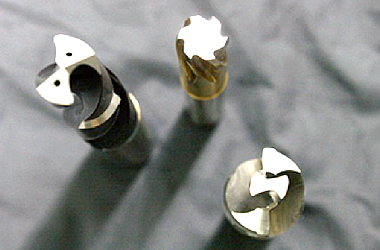

| Relief shape | Flat/Cone/Flat C/Cone F/Flat Brad | |

| Thinning shape | X/R/XR/BN | |

| Step part relief shape | Flat/Cone/Cone2 | |

| Tip chamfer | Flat/Cone/None | |

| Step shoulder chamfer | Flat relief/Cone relief possible only when step angle is 180° | |

| Reamer | Grindable shape | Right flute right hand; right flute torsion free; right flute left hand |

| Flute | 2~10 (2~6 when underΦ10) | |

| Point shape | 1st relief flat only/Flat | |

| Edge grinding | Grind/Not grind | |

| Before shape | Tip cut/Tip no cut | |